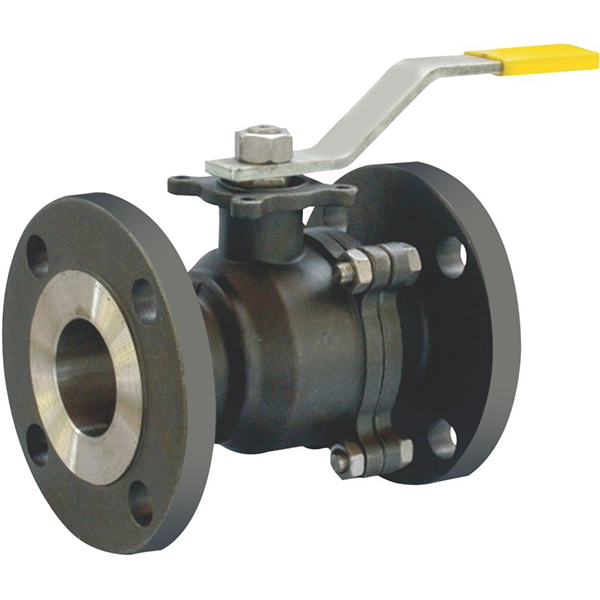

EXPERTS make Ball valves finds enormous application in the areas of Starting and stopping a flow, moderate throttling and Flow diversion. The valves are manufactured to the latest international designs, using advanced manufacturing techniques and stringent quality control checks. The ball moves across the seats with a wiping motion and therefore will handle fluids with solids in suspension. The seat matching the ball is circular and thus, from the point of sealing, the concept of the ball valve is outstanding.

Salient Features

- Moulded PTFE seats with slots Cavity pressure relief.

- Leak tight Stem sealing with one or series of Gland packing rings depending upon Valve size.

- Wide variety of seats and body seals.

- Blow out proof stem construction.